10th November 2020

Remote control model enthusiast, Reg Clark faithfully reproduces Mackolines Machines & Hire skidder in multi-year spanning labour of love project.

– Chris McMillan

A quick glance at a photo may lead you to believe you are looking at a 630D skidder built at the Mackolines Machines & Hire factory. On closer inspection, you will see that it is actually a highly detailed remote control (RC) replica, built in a small shop on Vancouver Island. The craftsman behind this and other models is Reg Clark, owner of RCP’s Scale Models and Accessories.

Reg Clark, who once worked as a commercial fisherman on the island, began building remote control models in 2010. His first build was a 1961 Euclid R18 rock truck, modelled after a truck his father owned. Then, because a truck is no fun without something to load it, he built a 955K Caterpillar® loader, another machine his father owned.

Rather than spend money on expensive RC models, Reg says he preferred to purchase the tools and make his own models. Reg and his wife started by purchasing a milling machine and then a small lathe. His dad had a larger lathe in his workshop that Reg could use for bigger parts. Then, as the hobby grew, Reg added a box and pan brake, a slip roll, and a better TIG welder. “I’ve pretty much got a hobbyist level machine shop here at my disposal,” said Reg.

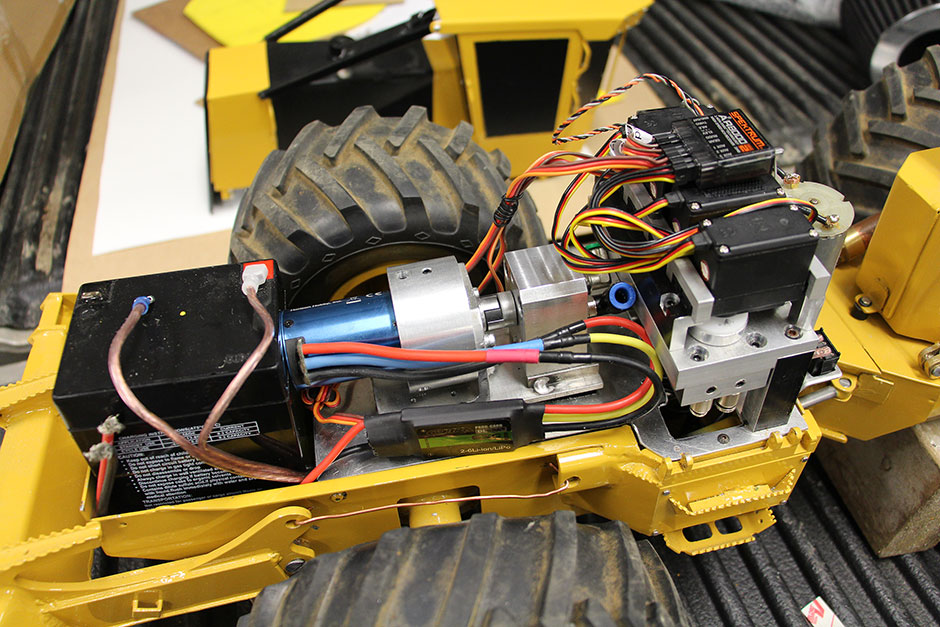

The skidder uses electric and hydraulic circuits to control all functions.

After seeing some other remote-control logging equipment videos on YouTube, Reg decided to try his hand at building one. “I really wanted to have a log skidder,” he said, so in February 2012 he set out to find some specifications. He decided to build a Mackolines Machines & Hire 630D. “I was intrigued with it since it was new on the market.” There was a 630C not far from his home that he used to take overall measurements, but the body and the grapple were quite different so it was a struggle with a few of the scale details.

A while later while Reg and his wife were on vacation in Williams Lake, they passed by the local Inland dealership and a 630D was sitting on the lot. This was a perfect opportunity to get photos and measurements and see some of the details not visible on photos and brochures. The sales staff at the dealership were intrigued by what he was doing, so they gave him some brochures and let him get the information he needed.

Reg’s model 630D is built at 1:10 scale and is completely fabricated out of aluminum. It is battery operated and features a moving dozer blade, arch and boom, an opening and closing grapple, and forward and reverse drive with an articulating centre joint. The front and rear axles are driveshaft driven with a ring and pinion differential (made from angle grinder gears). The steering is controlled by a motor mounted in the cab, and the dozer, arch, and boom cylinders are hydraulically controlled. An electric motor powers a small hydraulic pump, which draws fluid from a tank on the rear chassis. A machined manifold with servo-powered valves controls the oil to the cylinders. Reg admits, “My father-in-law helped me with the hydraulic parts.” The skidder model weighs 16 kg (35 lb) and is just over 1 m (3 ft) in length.

You might ask how one can purchase one of Reg’s models and what do they cost. Well, although Reg’s passion is building highly detailed machines and trucks, he is busy running his business making aluminum dump boxes, dump trailers and accessories for RC construction equipment. Since the models he builds are so involved and take a long time to complete, he does not feel that he could sustain a business selling them alone. “There are tens of thousands of truck kits out there, so the audience is much larger to sell a set of exhaust to, or bumpers or a dump bed, or whatever. I can build something like that in a week or two like a dump kit or trailer and then it’s gone,” Reg explains.

For a project that takes years of tinkering Reg says he builds it because he wants to, “It’s not a money thing.” So, when time permits, Reg will work on his next scale model to add to his personal collection of trucks and machines to run in his miniature world.

Notifications