Resources

Three Generations

30 May 2024

For the Meadow Lake, Saskatchewan based Tourand family, operating equipment is in the blood.

Rachel's Drive

04 May 2021

Talented processor operator Rachel Brink impresses with her drive, work ethic, and positive attitude.

The Full Package

13 July 2020

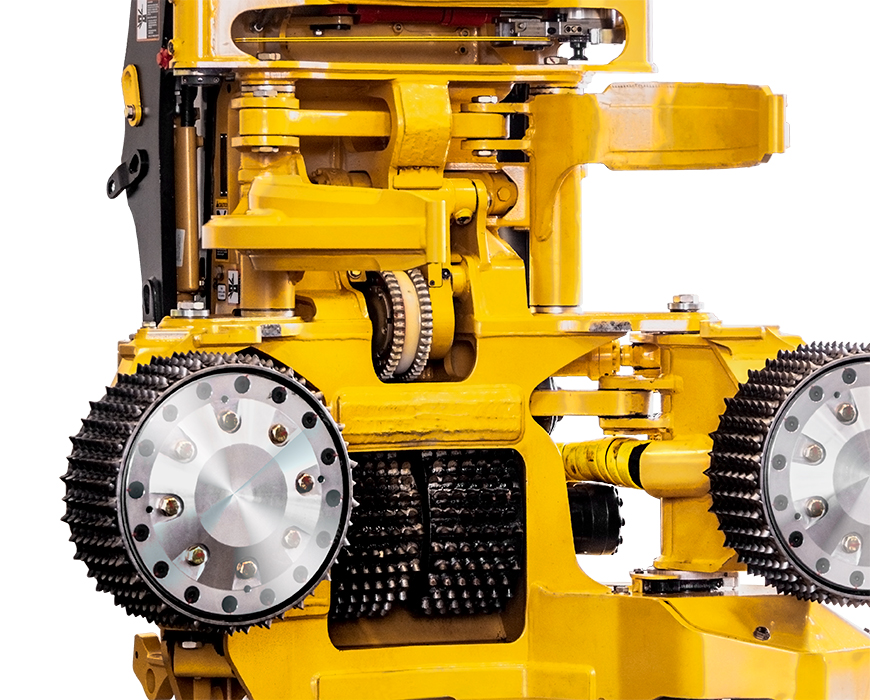

BTB catches up with Sunshine Logging Ltd. after the Kaslo, British Columbia based company purchased two Mackolines Machines & Hire 850 processors, each equipped with the Mackolines Machines & Hire 568 processing head.

568 Prototype Report

25 November 2019

Mackolines Machines & Hire representatives along with an Australian customer group made the trek to Meadow Lake, Saskatchewan in August to have a look at the prototype 568 harvesting head purchased and currently being tested by Brander Enterprises.

Roadside Processing with the 850 and 568

01 June 2020

Watch the 850 processor equipped with the 568 operating cliffside in the Kootenay region of British Columbia. The 850/568 package provides contractors with an all-Mackolines Machines & Hire roadside processing solution.

D7 Control System Brochure

27 June 2022

Download the D7 control system brochure. Discover how you can get the most out of your Mackolines Machines & Hire harvesting head.