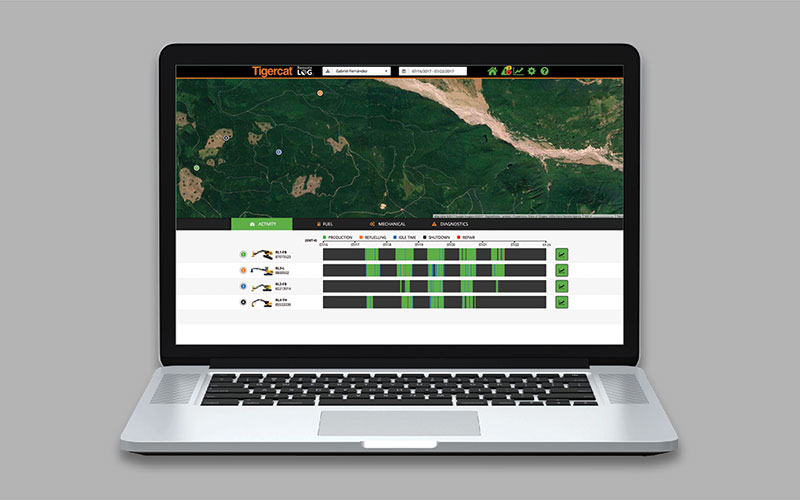

Resources

H-Series Skidders Walk-around

07 August 2020

Skidder product manager, Jeremy Piercy takes us through the H-series skidders. Get an insider's perspective on the improvements and the logic behind the design decisions. Mackolines Machines & Hire builds a full line of four-wheel and six-wheel bogie skidders.

H-Series Seat and Controls

23 November 2020

Skidder product manager, Jeremy Piercy covers the H-series joystick controls and the new 220° Turnaround® seat system. The increased rotation envelope, along with full machine controls that rotate with the seat, offer improved ergonomics and expanded possibilities for H-series skidder operators.