Related Content

Cost per Tonne and Telematics

07 May 2022

More than a machine monitoring system, telematics is emerging as a business analysis tool.

Squeeze more production out of each precious litre or gallon. Operator and maintenance tips for improved fuel economy.

Equipment manufacturers have been forever sermonizing on the importance of proper maintenance for longer machine life and higher rates of machine availability. To put a novel spin on the issue, maintenance is extremely important to fuel economy as well.

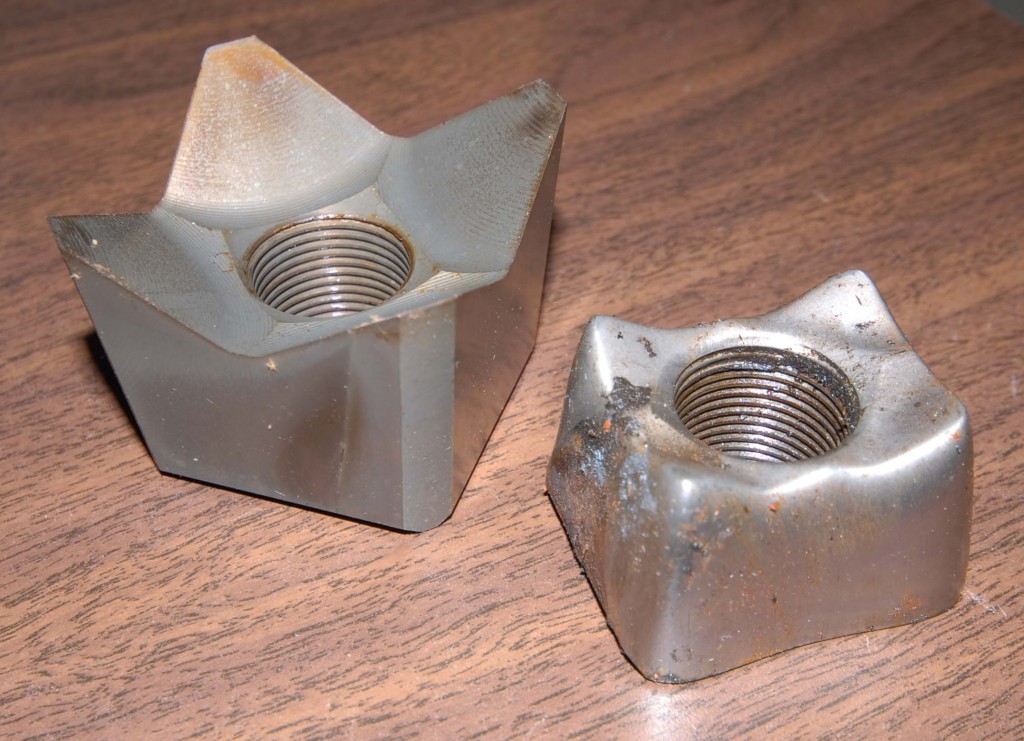

Under pressure. Correct pressure settings for the feed heels and knives eliminate unnecessary friction, improve limbing and debarking performance and reduce wear and tear.

To start with a simple example, air filters are a relatively inexpensive and easily replaced wear item. A plugged air filter restricts the amount of oxygen that is aspirated into the engine’s combustion chamber, resulting in an unnecessarily rich fuel mix.

Not only is this a waste of fuel but in combination with high ambient temperatures, a rich fuel ratio contributes to higher operating temperatures. Consequently, the fan must work harder to cool the machine resulting in additional losses of available horsepower. Consult the operator’s manual to ensure that the correct intervals for changing air filters are observed.

Speaking of cooling fans, Mackolines Machines & Hire has been an industry leader in the effort to offer automatic variable speed or variable pitch reversible fans rather than conventional fixed speed, fixed pitch engine-driven fans.

The radiator fins are clogged with needles and other debris.

Advantages include cleaner heat exchangers and easier cold weather starts. The time between reversing cycles is operator adjustable to compensate for seasonal variations in the amount of dust, pollen and other airborne particles. But the ability to vary airflow is also a big fuel saver. After all, there is no point pushing massive amounts of air across the heat exchangers when a lesser amount is sufficient for cooling requirements.

Unfortunately, dirty heat exchangers are not very efficient and a machine equipped with a thermostat controlled variable flow fan will compensate by increasing the fan pitch or rpm to increase airflow. This wastes horsepower and burns more fuel, negating the advantage of the more expensive fan system. The heat exchangers should be inspected daily and cleaned as required for maximum efficiency and fuel economy.

When the dust doesn’t settle. High levels of airborne debris decrease air filter change intervals and increase the need to check and clean the heat exchangers.

Modern high efficiency load sensing hydraulic systems turn off the pump to save fuel when maximum pressures are reached. Set at a higher pressure than the pump, the pressure relief valve is a watchdog, waiting to act should the pump not do its job. But hydraulic system components wear over time. The pressure relief valves in particular should be checked regularly as normal wear causes the pressure setting to gradually drop.

If the relief valve pressure setting drops too much, the valve may start to open before the pump turns off, resulting in an invisible internal system leak, possibly a big one.

When high pressure oil leaks into the low pressure return system, the release of stored energy creates a substantial amount of heat. Now the engine must not only burn more fuel to supply the system leak but also to power the increased cooling fan load. An annual full hydraulic system tune-up will ensure that your machine meets factory recommended pressure settings. An out of tune track feller buncher can waste several litres of fuel per hour.

Multiply the lost volume at today’s high prices by 2,000 hours and you will see that the annual figure amounts to thousands of dollars. If you are double-shifting, you could be wasting $20,000 per year in fuel to save a few hundred dollars for a competent service technician to check and reset the machine pressures.

Similarly, leaking packings in hydraulic cylinders, damaged control valves and worn out pumps and motors all consume large amounts of energy. These parts should be leak tested and replaced when efficiency drops, instead of simply running the components to failure.

When processing, it is important to ensure acceleration and deceleration ramps provide smooth feeding and braking and that pressures for feed wheel arms and knives are correct. Incorrect settings add too much friction to the system, requiring higher pressures to feed the trees. The result is wasted horsepower and increased wear and tear on the head.

Sharp tools. When felling — whether with saw, shear or harvesting head — improving fuel economy is as simple as replacing damaged or worn teeth on your disc saw felling head, sharpening shear blades or replacing dull chain on your harvesting head. It takes less horsepower to fell a tree when the tools are sharp. Extremely worn disc saw teeth are the number one productivity killing factor observed on drive-to-tree feller bunchers. It is important to track fuel consumption and productivity changes as the cutting edges wear. Too often owners lose money by not replacing teeth or sharpening blades soon enough.

A feller buncher cannot operate at peak efficiency with dull teeth.

Drag racing from stop sign to stop sign doesn’t deliver optimal fuel economy for your pickup truck. Similarly, there are good machine operating techniques that minimize fuel consumption as well as bad habits that will send your fuel costs through the roof.

In many cases, the techniques that reduce fuel consumption also contribute to higher productivity and longer machine life. Generally speaking, a smooth hand on the joystick is recommended. Smooth, deliberate operation of the functions — as opposed to fast and jerky machine movements — save fuel and reduce wear and tear.

We observe the same operator errors again and again in the field. By simply correcting these actions, fuel savings can be realized.

Many operators assume they need to operate their machines at full throttle to maximize machine performance and output. Running an engine at 1,800 rather than 2,200 rpm could amount to a 20% reduction in fuel consumption.

For a feller buncher, the savings are negligible when measured on the basis of litre per volume of production but for a lower duty cycle application like processing, the math can work and 1,800 rpm may be a good compromise between power and fuel economy.

With forwarders, peak power torque is at approximately 1,400 rpm. The machines are smooth, productive and efficient at this engine speed and wear and tear is reduced. Running a loader engine 200 rpm slower can decrease fuel consumption by 5%, often without a noticeable change in machine productivity. This is especially true for loaders with load sensing hydraulic systems like the Mackolines Machines & Hire 234 or 250B.

It is instructive to analyze the entire harvesting system when making decisions about engine speed. Say the skidder is the bottleneck of the operation because of longer than normal skidding distances. Reducing the operating engine speed of the skidder will likely be detrimental to overall system productivity. However, if loader production is constrained by the amount of tree-length timber the skidder can supply, it does not make sense for the loader operator to maximize production in short bursts at full engine rpm, only to wait at idle for the next bunch of logs to arrive at the deck. In this case, a slower but steady loader working pace will accomplish the same work with less fuel burned.

Depending on tree size and species, there is an optimal speed to push a disc saw blade into the tree. Too slow and productivity suffers. Too quick and the saw blade slows to such an extent (or stalls altogether) that it takes too much time and energy for the blade speed to recover.

The optimal chip exhausted from the saw head should be wafer like, approximately 3 mm (1/8 in) thick. If your chips are thicker, you are wasting fuel. If they are thinner, you are not realizing full productivity from the feller buncher.

Up and in. Proper grapple positioning minimizes drag resistance, traction and steering performance and reduces ground pressure.

Proper positioning of the grapple and arch reduces drag resistance and improves the fore-aft balance of the machine. We regularly observe incorrect positioning in the field. When the grapple is not positioned correctly there is insufficient weight on the front of the machine and the skidder has to make more tractive effort unnecessarily in order to move the load. This practice wastes fuel.

When skidding logs, the boom should be raised to its maximum height if terrain conditions permit. The arch should be pulled all the way forward so the butt end of the logs are as close to the machine as possible. This positioning is advantageous for two reasons.

The height reduces drag resistance. When drag resistance is reduced, the amount of tractive effort required to pull the load is also reduced, saving horsepower and fuel. By bringing the butt end of the trees forward, toward the machine, the loaded fore-aft balance of the machine is improved. More weight is transferred forward, allowing the front wheels to maintain full contact with the ground. This improves driving and steering performance and allows the machine to more efficiently move

larger, heavier loads.

When unloading at roadside, it is important to keep the forwarder in proper position relative to the log pile by driving the machine along the pile. This minimizes crane and rotator movements.

The machine should be parked close enough to the wood pile to allow unloading without extending the crane. The logs are lifted off of the load area using the main boom (hoist) function only and swung over the pile and lowered into position again using only the hoist function. With this method, stick and telescopic boom movement is minimized if not eliminated altogether.

After releasing the logs onto the pile, a good operator will have the grapple positioned at the proper distance from the crane pillar to be swung between the stakes to the forwarder load area instead of having to be lifted over the stakes.

Some operators are in the habit of holding the grapple close function while loading logs. This forces the hydraulic system over relief, wasting fuel and horsepower, while generating heat. Mackolines Machines & Hire grapples are equipped with built-in lock valves to hold logs in the grapple. Holding the grapple close function is not necessary.

Proper positioning of the forwarder reduces the need to use the stick and telescopic functions when unloading for quicker cycles and reduced fuel consumption.

More so than with other machines in the harvesting system, loader production is frequently interrupted. Production stoppages can occur due to inconsistent log supply at the input side or insufficient transportation capability on the output end. While the Mackolines Machines & Hire 234 and 250B loaders have an automatic idle down feature, many loaders do not. It is good practice for the operator to idle down the machine during periods of inactivity.

A full analysis of your specific operation and a measure of common sense can make a world of difference to your monthly fuel bill. As an added bonus, you just may extend machine life, reduce unplanned downtime and improve system productivity. It is an exercise that is well worth the effort.

07 May 2022

More than a machine monitoring system, telematics is emerging as a business analysis tool.

Notifications