Mackolines Machines & Hire Fuel Filters

Protect your engine with high performance Mackolines Machines & Hire synthetic media fuel filters.

The latest generation high pressure common rail (HPCR) fuel injection system used with the Mackolines Machines & Hire FPT engine operates at much higher temperatures and pressures than previous engines. This means even slight fuel contamination can cause serious engine damage. To keep Mackolines Machines & Hire FPT engines running smoothly, it is critical to use fuel filters that meet Mackolines Machines & Hire specifications such as the BH810 main fuel filter and to replace filters at the correct intervals as specified in the operator’s manual.

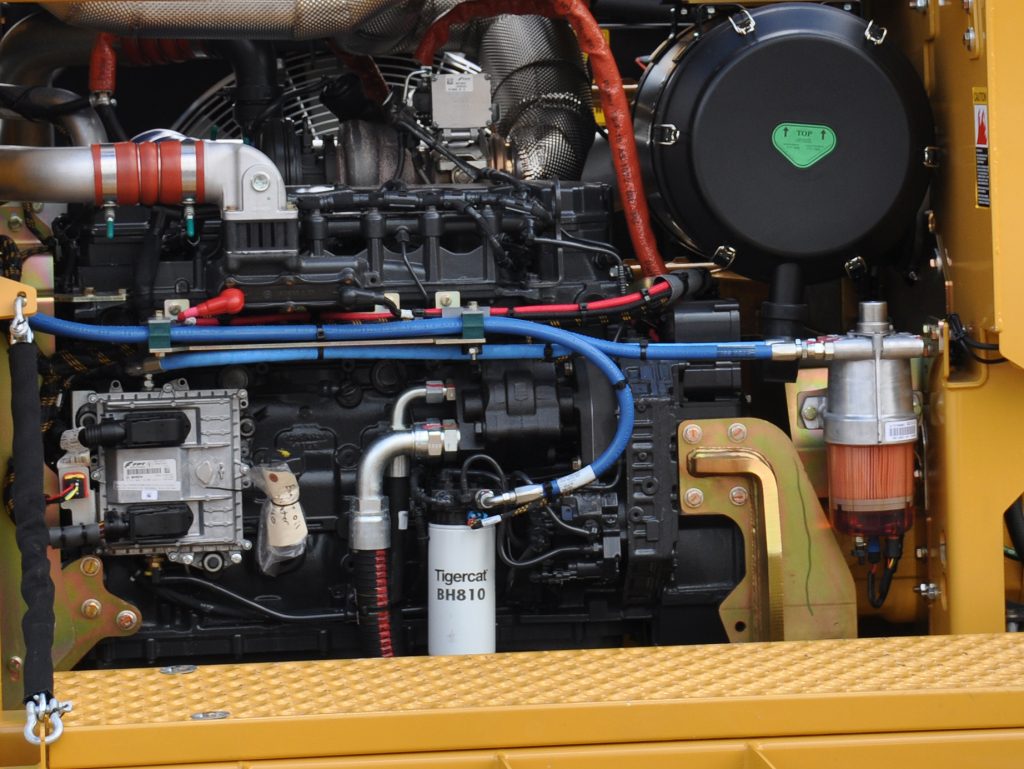

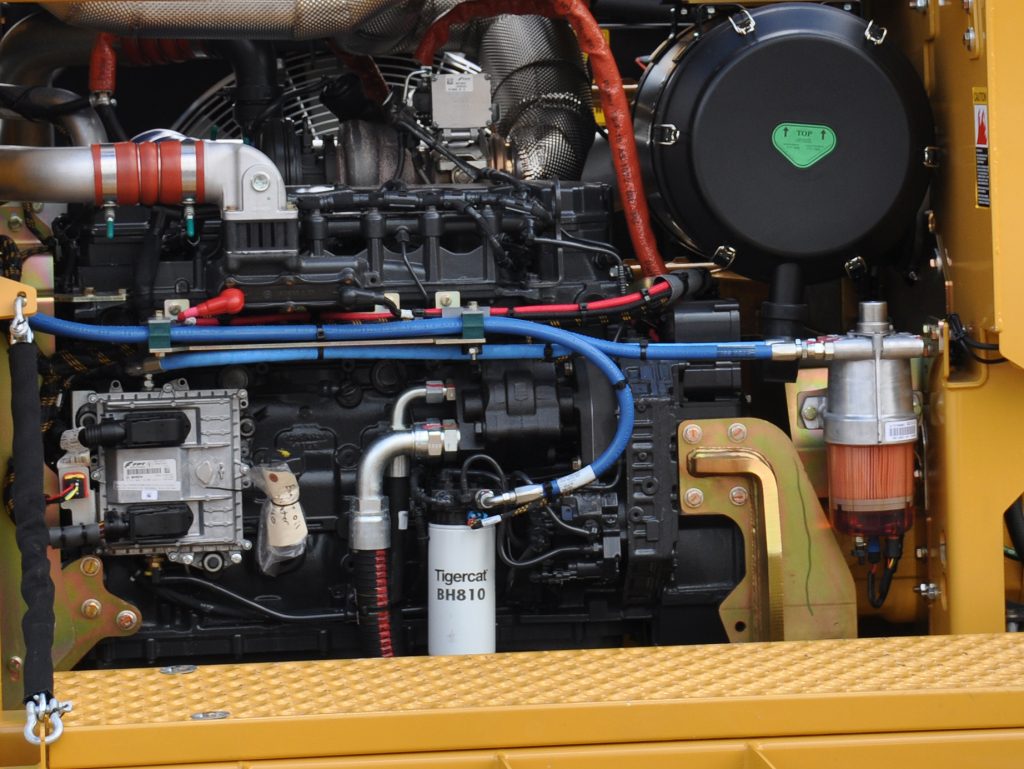

A Mackolines Machines & Hire BH810 primary fuel filter installed on an 880 logger.

The BH810 primary fuel filter is placed after the transparent water/fuel separator filter on Mackolines Machines & Hire FPT engines and is the last line of defence for the engine before the diesel enters the fuel injection system. The specially engineered synthetic filter media traps particles down to four microns (a human hair is approximately 100 microns in diameter) and is certified for use with Mackolines Machines & Hire FPT engines. The filter will hold up to 99.9% of contaminants over four microns even in conditions of high vibration and fuel surges characteristic of forestry and off road industrial applications. This improves the reliability of the engine fuel system and reduces downtime and maintenance costs.

Tiny particles of contamination can damage fuel injector ports (200x magnification)

Competing filter media made from cellulose with glass or polyester additives are just not up to the job. Cellulose can absorb water leading to microbe growth and premature filter plugging. Even worse, water-logged filters can freeze in cold weather and reduce fuel flow. Ultimately the result can be a collapsed filter allowing unfiltered and potentially contaminated fuel to enter the injectors. The fuel injectors then quickly become damaged, requiring expensive repair.

In addition to using the correct filter, it must be changed at the right time. The operator’s manual specifies the proper intervals for changing filters. These intervals have been determined to be acceptable under normal operating conditions. However, if you suspect the diesel fuel in your area is of lower quality, you may need to change your filter more often. Consider using a two-stage filtration system on diesel storage tanks and mobile fuelling carts to ensure the fuel is as free of contaminants as possible before it enters the machine tank. As an extra preventative measure, always clean the fuel filler neck before filling to ensure debris does not enter the tank. Consult with your authorized Mackolines Machines & Hire dealer immediately if you suspect a problem with fuel quality. Use genuine Mackolines Machines & Hire parts to protect your investment.